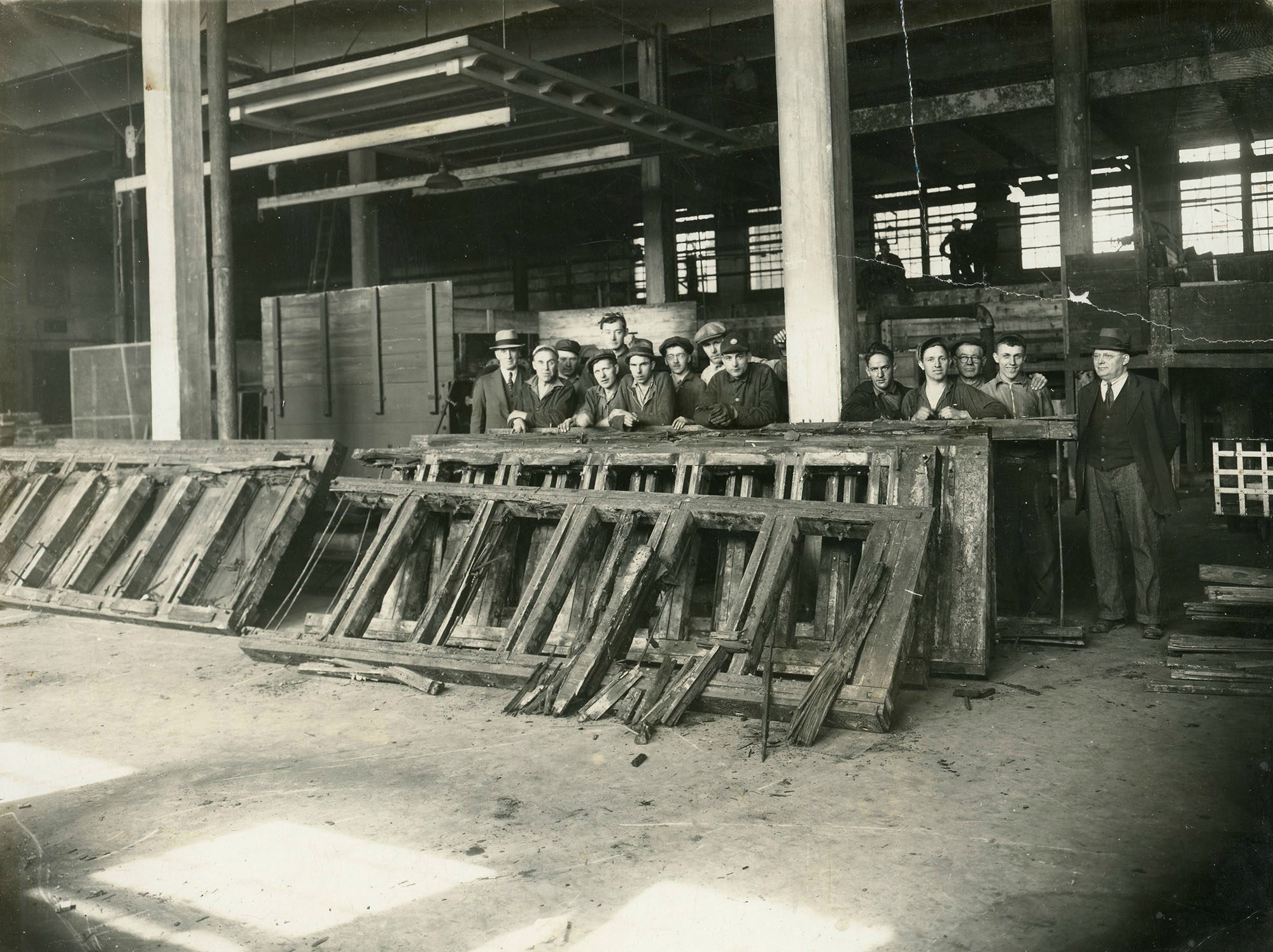

Sulfite Mill bosses and workers in Dexter

Employees in Dexter Sulfite Mill, which was the first in the US to make pulp through a chemical process using sulfuric acid, called the Mitscherlich process. Donated by Bernard Burke. Circa 1900. Dexter, NY.

Editor’s Note: The information below was taken from an article we scanned from the Dexter Historical Association. We cannot find an attribution for the publication from which it was drawn. If you know, let us know.

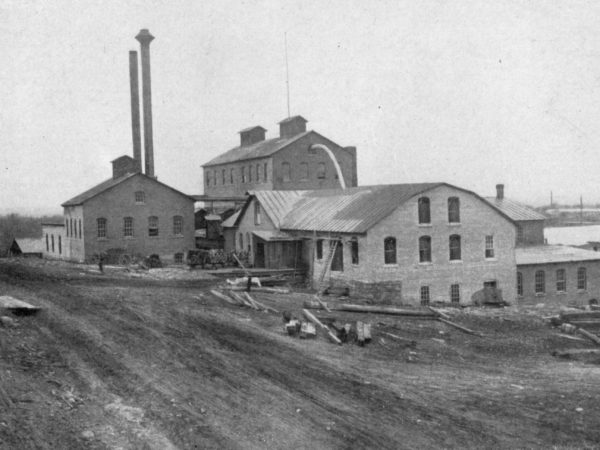

An old woolen mill was converted. Two new concrete wings were added, and three dams were rebuilt in 1888 and 1889. The power canal was rebuilt and enlarged. The old dye house of the woolen mill was razed to become the digester room and a boiler house. Jenssen acid towers were added to the mill complex.

The Mitscherlich process–known as the sulfite method–was a new way to produce paper, using sulfite to produce the heat necessary to form pulp. This type of pulp was made using only indirect steam instead of internally injected steam as in every other process.

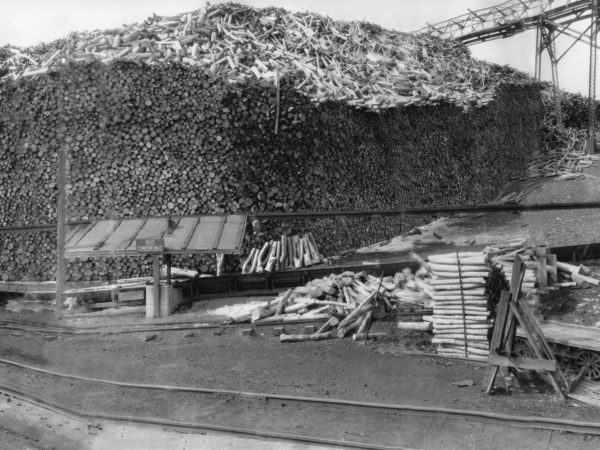

To make paper this way, the plant needed digesters, of which it eventually had eight. The challenge was getting the 40X13 foot mammoth steel shells to Dexter. Each digester was made of 3/4 inch thick steel and weighed forty tons. Ultimately, the digesters were floated across the lakes from Cleveland to the piers in Black River Bay. From the Bay they were rolled all of the way to the mill. The digesters held nine tons of pulp each, and they cooked the pulp for a fifty-hour period.

North Country Public Radio is not the owner or holder of copyright for any images within the North Country at Work archive. For uses of a photo (other than educational or non-commercial purposes), contact the photo’s institution of origin.